Product Description

Varnished Copper Wire for Electric Motor Winding is a vital and efficient component used in the winding process of electric motors. It features a high-purity copper core coated with a thin layer of insulating varnish, ensuring excellent electrical conductivity and reliable insulation performance.

Key Features

- High Electrical Insulation thanks to heat- and moisture-resistant varnish.

- Superior Flexibility for easy winding and shaping during motor manufacturing.

- Corrosion Resistance for long-term durability in harsh environments.

- Stable Thermal Performance under high operating temperatures.

- Excellent Conductivity that enhances motor efficiency.

- Industry Compliance with international standards for electric motor components.

Purpose & Benefits

- Boosts motor efficiency and reduces electrical losses.

- Extends motor lifespan through enhanced insulation and corrosion resistance.

- Simplifies manufacturing and maintenance due to wire flexibility.

- Ensures stable performance in demanding industrial environments.

Practical Uses

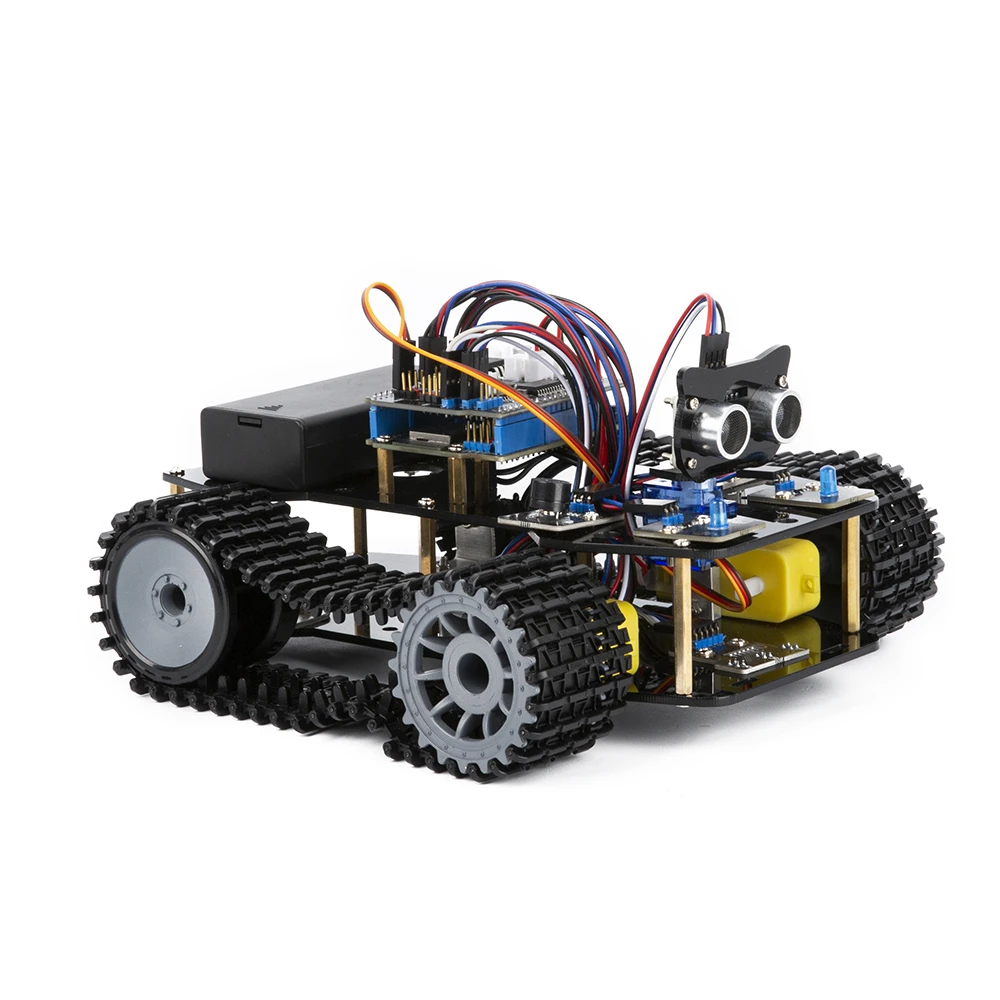

- Winding of single-phase and three-phase electric motors.

- Manufacturing of transformers and inductive coils.

- Repair and maintenance of household and industrial electrical devices.

- Renewable energy projects such as wind turbines and solar generators.

Versatile Applications

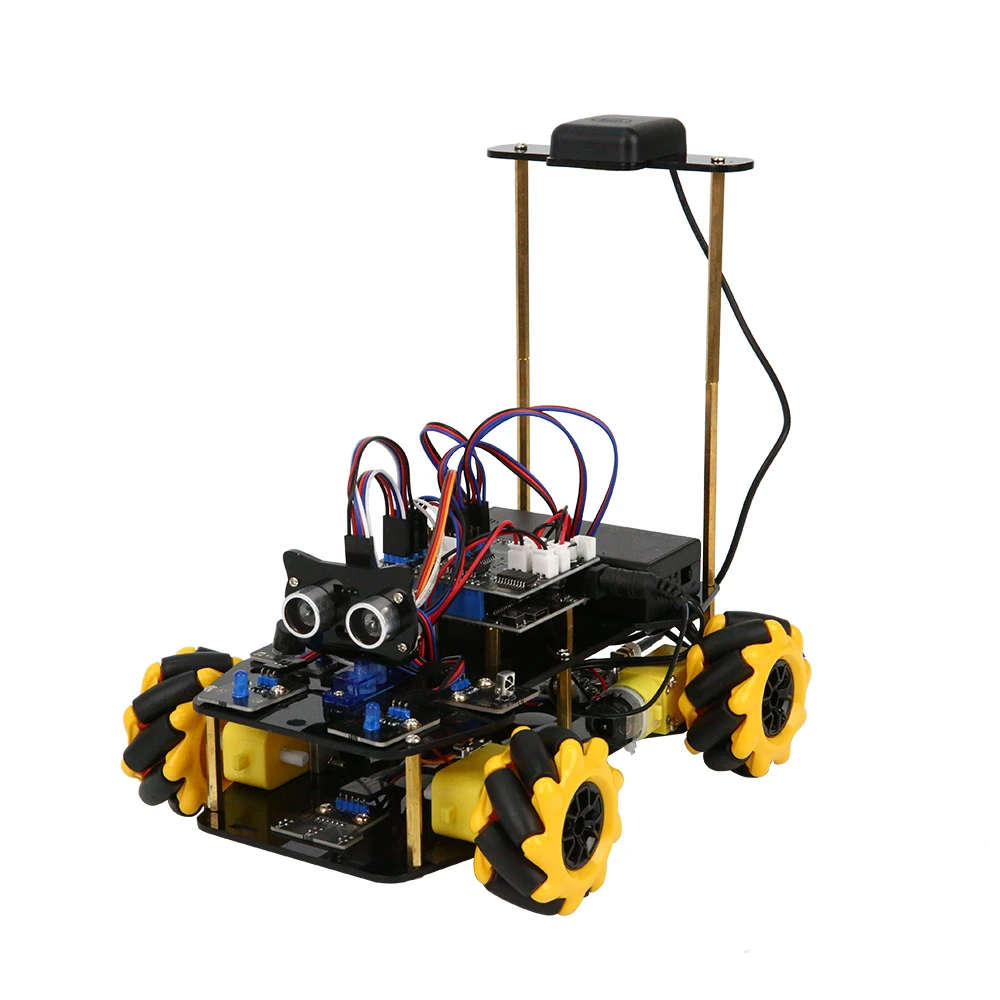

- Ideal for motor manufacturers, repair technicians, and energy engineers.

- Used in heavy industry, home appliances, and agricultural machinery.

- Suitable for vocational training centers and technical education labs.

- Applicable in R&D projects focused on energy and electromechanics.

Quality & Innovation

This wire stands out for its high manufacturing quality and advanced insulation technology. The varnish provides dual protection against heat and moisture, giving it a competitive edge in terms of reliability and operational lifespan.